Metal 3D Printing

Metal 3d printing, also known as direct metal laser sintering (DMLS) and direct metal laser melting (DMLM) is an additive layer technology. A metal 3d printer utilizes a laser beam to melt 20-60 micron layers of metal powder on top of each other. Powdered metal is spread across the entire build platform and selectively melted to previous layers. This additive process allows metal parts to be grown out of a bed of powdered metal. The process is like other polymer based 3D printers that use powder bed fusion.

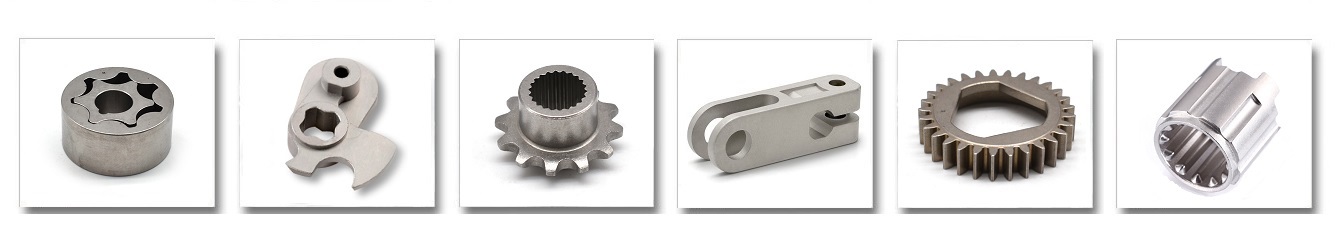

Metal 3D printing is a revolutionary technology that produces impossible-to-make parts directly from your CAD data. This technology combines the design flexibility of 3D Printing with the mechanical properties of metal. From tooling inserts with cooling channels to lightweight structures for aerospace, any application that involves complex metal parts potentially benefits from Metal 3D Printing. Advantages to this process include the ability to produce strong, complex geometries, internal lattice structures, conformal cooling channels and other features that cannot be made with traditional machining. Parts can be made quickly with a minimum of material waste making them ideal for next-generation engineering in aerospace, medical, automotive and other industries.